The Challenge of Dehydration in Freezing IQF Berries: Why and How to Face it.

Product dehydration (loss of water) during the freezing process plays a crucial role in determining the quality and weight of the final product. It poses a significant challenge to berry processors, impacting their yield and profitability.

This challenge becomes even more critical when dealing with berries, which have a higher water content ranging between 85% and 92%. Therefore, it is essential for food processors to gain a comprehensive understanding of how product dehydration occurs to allow for a better control of the process and minimize profit loss without compromising product quality.

How Does Production Dehydration Occur?

When the product is exposed to low-temperature airflow, the difference in humidity between the product and the surrounding air causes moisture loss. This moisture is released though the product's membranes, leading to dehydration. While product dehydration during freezing is an inevitable occurrence, there are effective methods to minimize moisture loss.

Several factors contribute to dehydration during the freezing process. Firstly, keeping the freezing time as short as possible can achieve rapid crust freezing, effectively locking the moisture inside the product. Secondly, the aerodynamics within the freezer, determined by temperature, air pressure, airspeed, and humidity, play a vital role. Controlling these factors is crucial to prevent snow formation, a clear indicator of high levels of dehydration.

In a closed freezer environment, the moisture that precipitates into snow can only come from the product. This occurs when the air's relative humidity reaches its saturation point. When combined with low air velocity and incorrect temperature and air pressure, the formation of an ice nucleus becomes more likely, leading to snow formation.

Two Ways to Control Product Dehydration

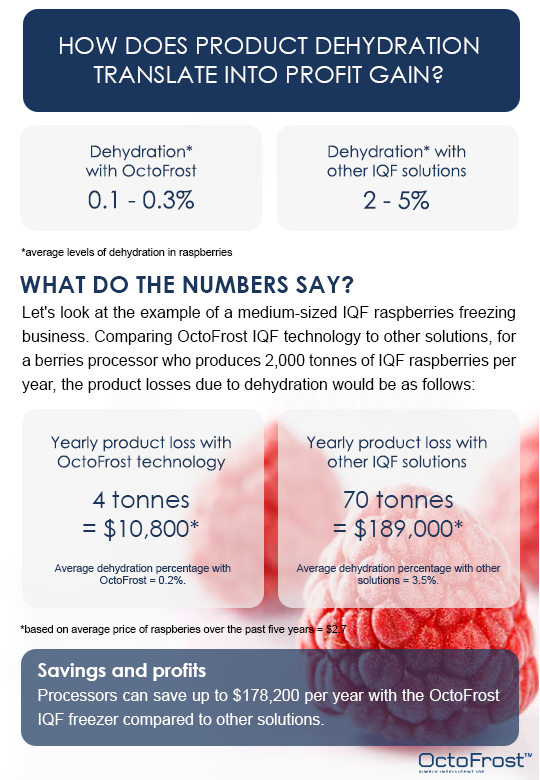

OctoFrost's customers report dehydration levels ranging between 0.1% and 0.3% on average, depending on the specific product. In comparison, other solutions on the market often reach dehydration levels of 2% and 5%. So how do we achieve such remarkable results?

The key lies in the freezer's adjustable fan speed, which creates customized aerodynamics for each product type. By optimizing the combination of airspeed, air pressure, and relative humidity for each application, product dehydration is minimized. The unique airflow and airspeed balance, coupled with continuous circulation, significantly reduces moisture loss.

Preserving Premium Berries with Minimal Dehydration

When it comes to processing berries, controlling water loss becomes even more critical due to their high water content. At OctoFrost, we understand the importance of preserving the quality, appearance, and weight of premium berries. Our customers attest that fluidized freezing, unlike static freezing, provides exceptional efficiency without compromising quality, enabling the processing of larger quantities in a shorter time.

Finding the optimal balance of airflow and speed poses a challenge. Excessive airflow can cause moisture loss, while insufficient airflow slows down the freezing process. However, with the adjustable airflow, processors can meet optimal conditions for each type of berry. This results in energy efficiency, higher yield, and premium berries, while allowing you to take full control of product dehydration.