Selling Highest Quality IQF Berries: Challenges and Solutions

Berries are particularly delicate products that pose one great concern to processors: maintaining their natural appearance and shape during the freezing process. High water and sugar content are among the main reasons that make berries a difficult product to handle. As a result, three main challenges can arise during the freezing process: lump formation, product dehydration, and surface cracking or crumbling. These can significantly affect the quality of the final product, ultimately forcing the processors to sell at lower prices.

In order to maintain high profitability, processors need to ensure the premium quality of the berries. This is achievable thanks to modern freezing solutions like the OctoFrost IQF freezer, which matches the particularities of the berry and handles each variety with care. In response to the above-mentioned challenges, fluidization and flash-freezing have proven to be the ultimate solution for premium berries.

IQF tailored solutions for berries of unrivaled quality

As a result of increasingly warmer weather around the globe, many regions where berries used to be mass-produced are experiencing less consistent berry production. On the contrary, the demand for frozen varieties has been growing. In fact, according to Grand View Research, frozen berries are expected to grow at the fastest rate of 7.5% between 2022 and 2027.

Crust-freezing zone for perfect separation

Due to their high water content, berries present a sticky surface that can easily lead to the formation of clumps or large ice blocks. To prevent this from happening, the OctoFrost™ Freezer uses multiple freezing zones, each with adjustable fan speed to allow for optimal air pressure and speed. In the first zone, OctoFrost offers a crust-freezing belt that immediately freezes the surface of the berry prior to freezing its core in the next zones. This helps to keep the pieces separated from each other, thus avoiding lump formation and preserving their natural shape during the freezing process.

Fast-freezing to prevent product dehydration

Long freezing times can damage the cellular structure of the berries' molecules and lead to loss of moisture, resulting in weight loss and a change in color and texture. The key to preventing this is a perfect airflow inside the freezer that can shorten the freezing time to just a few minutes. This is achieved by the optimal aerodynamics created in the OctoFrost IQF Freezer. Its compact shape and adjustable fan speed contribute to keeping the size of the ice crystals small and product dehydration to a minimum. Less dehydration equals higher yield, which means greater profits for processors.

Bedplate technology for achieving a natural appearance

One of the most challenging aspects of freezing berries is avoiding surface damage. The use of metal mesh belts and long freezing times are among the main causes of the problem of surface damage. In the case of blueberries, they usually cause surface cracks, while when it comes to other varieties, such as raspberries, they can lead to breakage and crumbling.

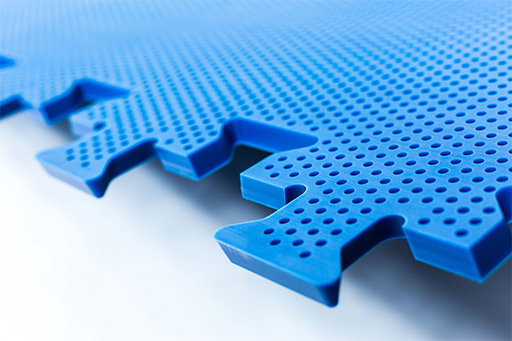

As a solution, OctoFrost developed the patented bedplate technology with food-grade plastic material. With the help of careful movement and vibrations, the bedplates move the berries forward gently and steadily, ensuring good separation and avoiding surface damage.

A way forward

Adapting your technology to match the market needs and keeping constant track of innovations and new developments is paramount to the long-term success of your IQF business. A premium quality frozen product will naturally lead to better grading, better pricing and higher profitability.